ABOUT THE MACHINES

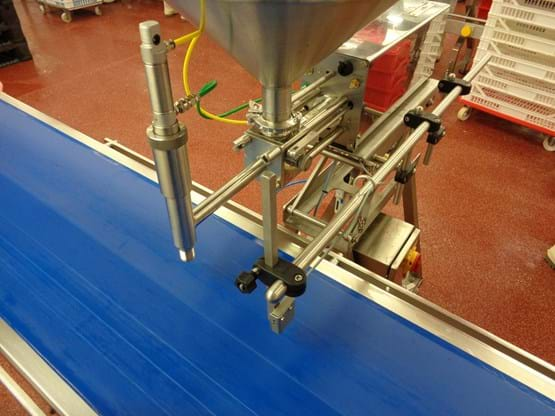

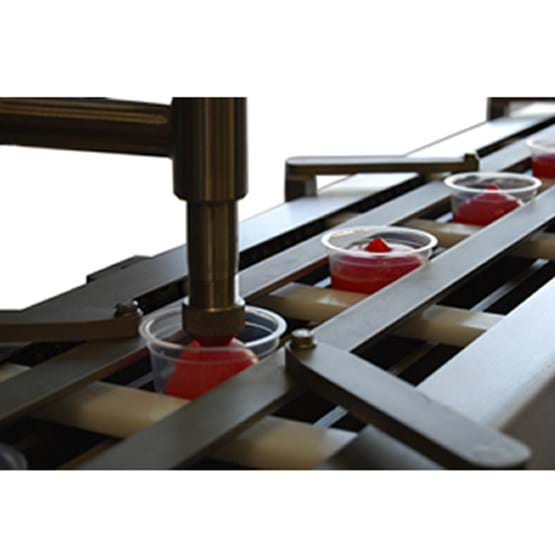

Our range of depositing machinery has been developed to deliver accurate doses of liquids & liquids with suspended semi solids.

The Winyard Engineering depositors range can accurately & repeatably dose from 5ml up to 5,300ml with typical variance of less than 1%.

Fully pneumatic in operation we remove the requirement for electrical supplies in wet areas.

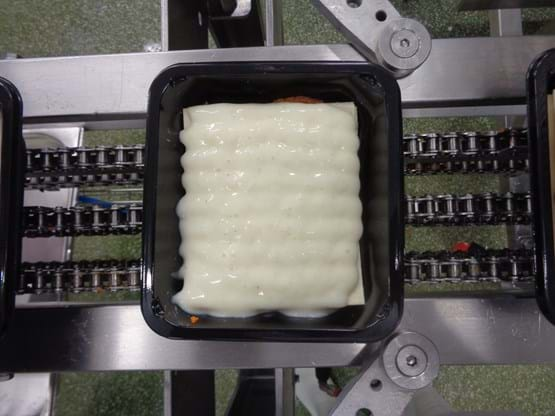

Typical applications include oil & vinegar based dressings, soups & sauces, ready meals, coleslaw & wet salads, yoghurt & hummus, cake batter & frosting, peanut butter & jam, and many, many more.

Standard Features

- Stainless steel and food grade materials construction.

- Quick dismantle and reassembly times for cleaning.

- Fully adjustable speed control.

- Simple volume adjustment.

- Readily available port for external foot pedal / fill signal.

- Air filter regulator.

- Foot pedal or air signal control.

- All consumables available from stock.

Optional Features

- RJT or Tri - Clover fittings.

- General purpose cut off nozzles from 20mm to 50mm diameter.

- Rise & fall nozzles from 20mm to 36mm diameter.

- Liquid cut off nozzles.

- Rotary spreading nozzles.

- Positive ported units for pressure feed systems.

- High temperature seals.

- Stainless steel hoppers from 5 litres to 250 litres.

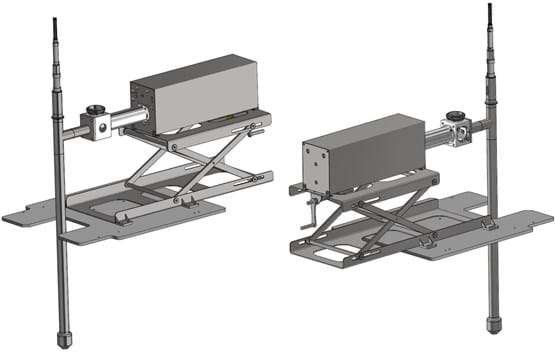

- Range of stainless steel stands including conventional scissor stands, single column stands, low level trolley stands, combination stands and vertical stands.

- Hopper level control systems.

- 24v DC tip signal control.

- Electrical sensing & automation pack to remove operator intervention.

Machine Ranges

Micro Fill

- Displacement up to 120ml per stroke

- Hopper capacity 5 litres

- For free flowing products including fine particulates

- Cold fill only

- Rise & Fall type nozzle as standard

- Ideal for the injection of cakes and pastries with jam, sauce or cream

- Table top stand

- Slim line design

Eco500

- Entry level filler for ease of use and no tool stripdown

- Low air consumption

- Displacement up to 500ml per stroke

- Hopper capacity 30 litres (standard)

- High or low frame mounting possible

- Cut off nozzles from our extensive range to ensure clean, repeatable presentation

- For all products with particulates up to 20mm

- Product fill temperatures from 0 degrees up to 40 degree Celsius

- Ideal for short production runs

Mini-Fill

- Filler displacement up to 410ml

- Up to 100 fills per minutes depending on product

- Hopper capacity 40 litres as standard

- Low/Mid/High level stands available

- Extensive range of cut off nozzles to ensure clean, repeatable presentation

- For a variety of products including those with particulates up to 25 mm

- Hot and cold filling

- Typical applications include ready meals, sandwich fillers, dessert production and many more

- Optional equipment includes various hopper sizes and styles. Automated sensing packages. Retro fit option to customers existing machinery. Positive porting to suite pressure fed systems.

Midi-Fill

- Filler displacement up to 1.25 litres

- Hopper capacity 60 litres as standard

- Low/Mid/High level stands available

- Extensive range of cut off nozzles to ensure clean, repeatable presentation

- For a variety of products including those with particulates up to 30 mm

- Hot and cold filling

- Typical applications include soups, coleslaw's, sauces, pie mix and many more

- Automated sensing systems available

- Positive porting to suit pressure fed systems

- Assisted hopper feed system for non flow able products

Magnum-Fill

- Filler displacement up to 3 litres

- Hopper capacity 95 litres as standard

- Low/Mid/High level stands available

- Extensive range of cut off nozzles to ensure clean, repeatable presentation

- For a variety of products including those with particulates up to 35mm

- Hot and cold filling

- Typical applications include bulk packaging of food products and many more

- Automated sensing system available

Mega-Fill

- Filler displacement up to 5 litres

- Hopper capacity 95 litres as standard

- Low/Mid/High level stands available

- Extensive range of cut off nozzles to ensure clean, repeatable presentation

- For a variety of products including those with particulates up to 35 mm

- Hot and cold filling

- Typical applications include bulk packaging of food products and many more